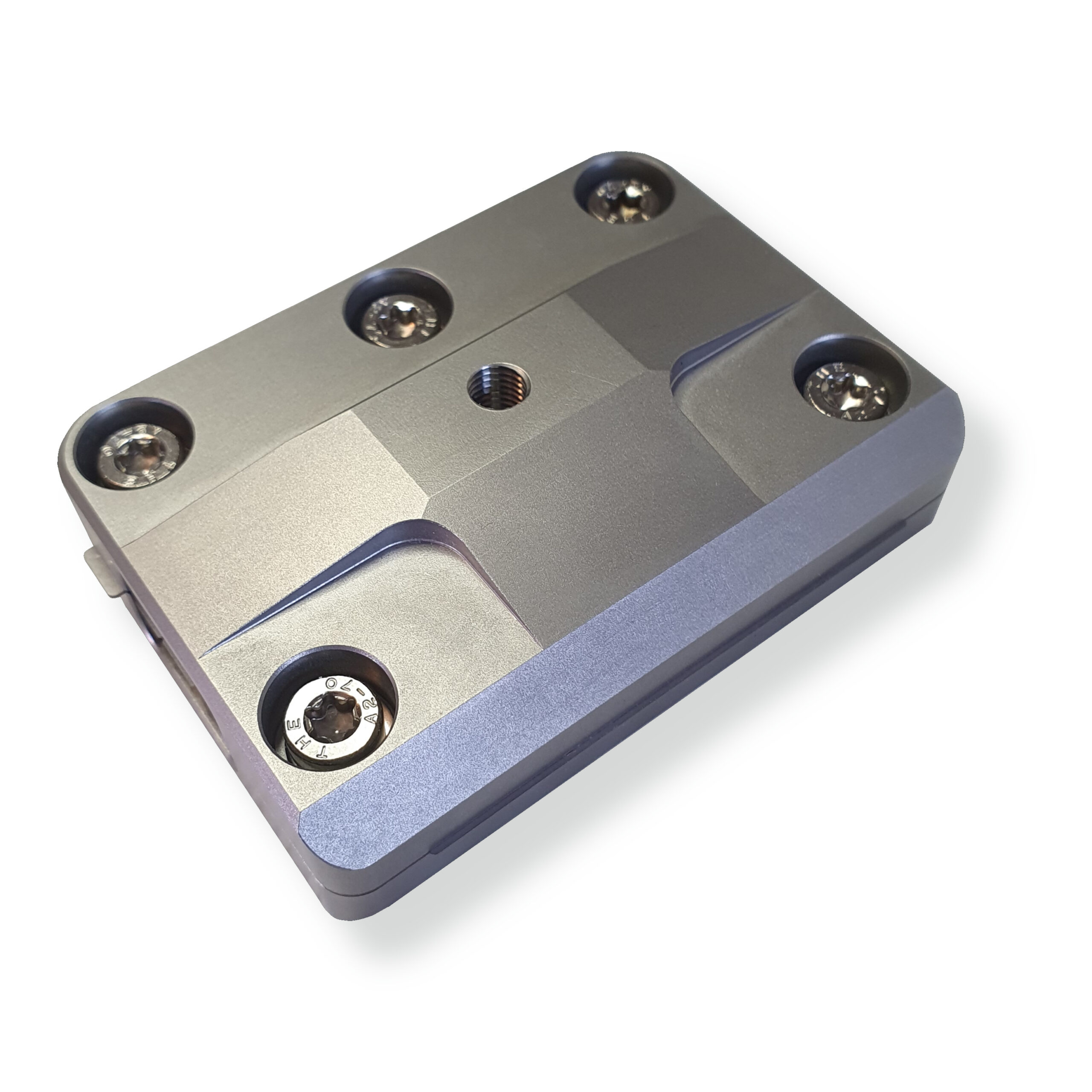

Slot-Die Heads

Discover our advanced slot-die coating components. Our slot-die heads come with an unique shim set, which ensures a constant coating gap along the coating width. It minimizes dead volume and a single slot -die can be used with different shims to account for different fluid viscosities or different coating widths.

For high quality slot-die coating processes, a constant coating gap (or slot width) is required. Shim systems are used especially in research and development to allow variations in coating width by using different shims. The gap width can be varied by using shims of different thicknesses or by stacking shims. In many cases, the resulting coating gap is not uniform across the coating width because the shims can bow towards the center of the slot die. This makes process development cumbersome and the reproducibility of the process is often even strongly affected by the way the slot-die is assembled.

Benefits of the advanced shim design

- Our solution provides a constant coating gap width and minimizes dead volume.

- The fluid is evenly distributed in the slot die by a carefully optimized system of channels. The channels are created by stacking the appropriate shims.

- In this way, very little bowing can occur as all distances in which the metal plates are not supported are minimized.

Our standard shim set (made of stainless steel) is designed for coating widths of 55 mm and a shim thickness of 75µm.

The slot-die itself is fabricated from stainless steel and has a total width of 75 mm.

Please contact us for custom geometries

The slot-die can be mounted on our LP50 slot-die integration kit or also on most other platforms, please indicate in your inquiry whether you want to use it with the LP50 or not. In the first case you will need the integration module and in the second case an adapter plate is required.