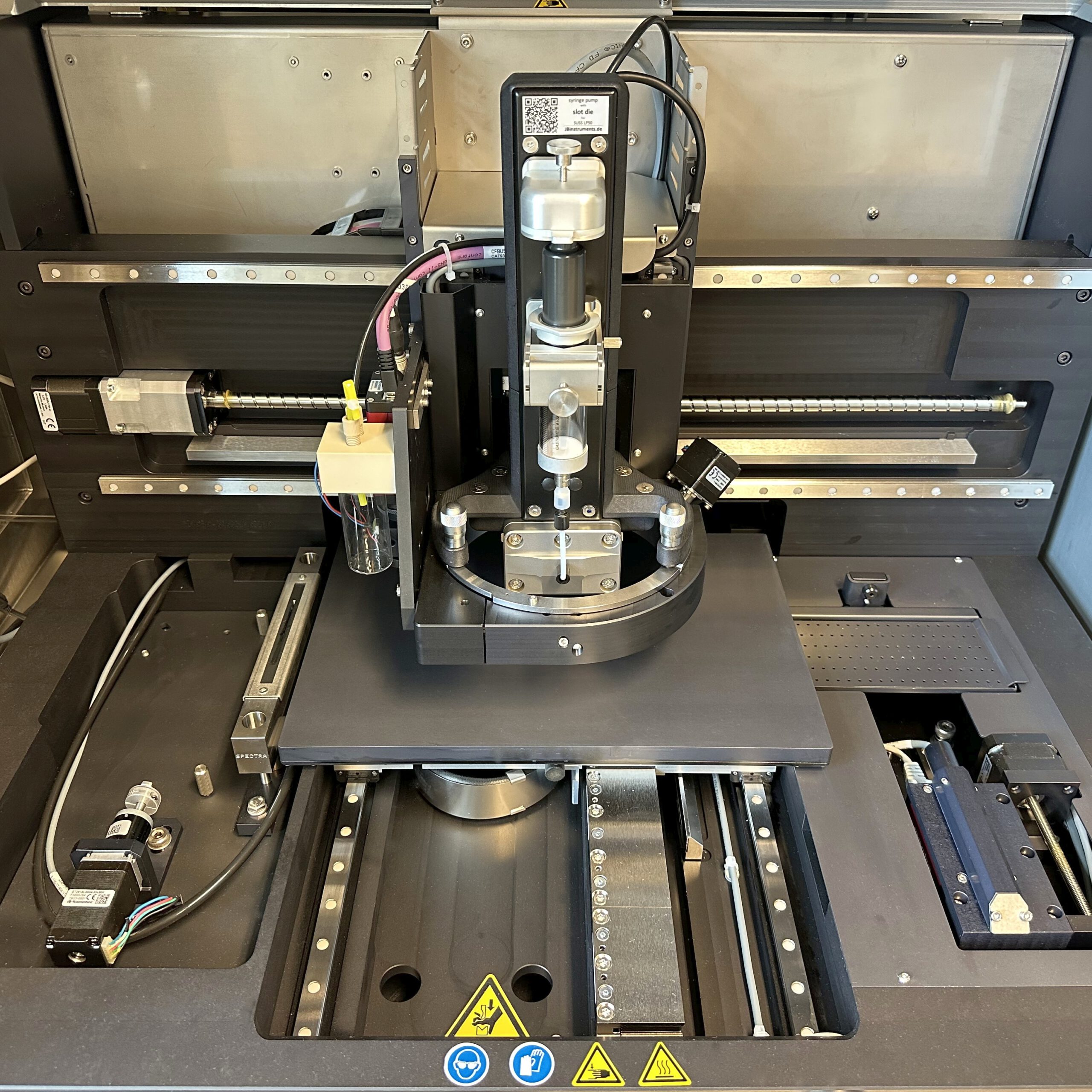

Slot-die Coating Module for SUSS LP50 Printer

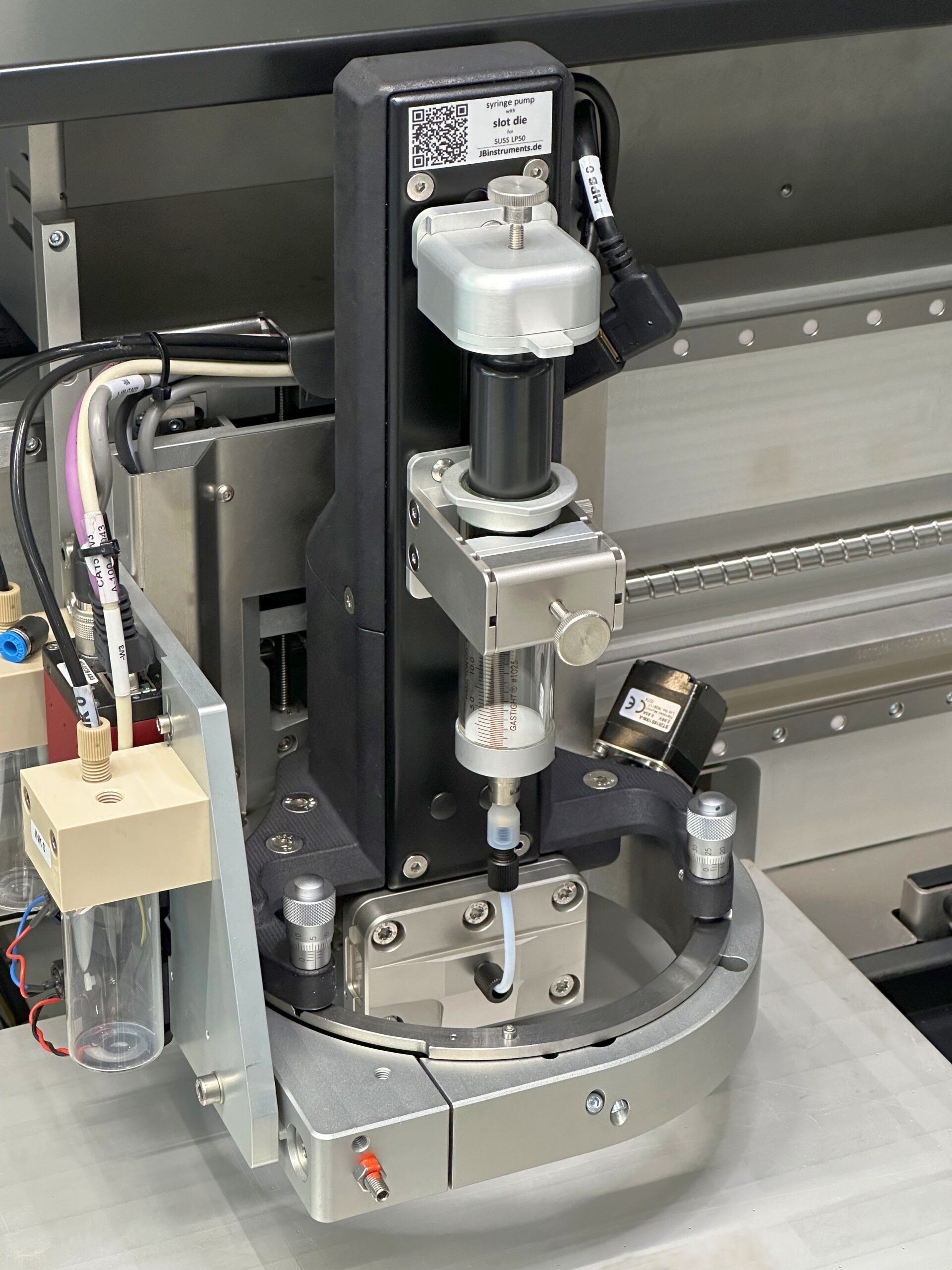

The SUSS LP50 printer is a powerful workstation supporting a wide range of processing technologies. The novel slot-die coating module from JB Instruments turns the LP50 printer into a high precision sheet to sheet slot-die coater with unprecedented flexibility. This way inkjet and slot-die coating processes can be carried out using the same machine minimizing investment and footprint in the lab. The camera system and the flexible motion capabilities of the LP50 allow precise adjustments, control and things you cannot do with any other slot-die coaters for example printing multiple coats next to each other with different parameters in one run.

In research and development the efficient use of materials and lab space are very important. We have learned that for most R&D applications it is sufficient and practical to work with a syringe pump allowing reproducible materials transport and coatings with small or very small amounts of material. There is nothing worse than losing most of the carefully prepared material in tubing and other dead volume.

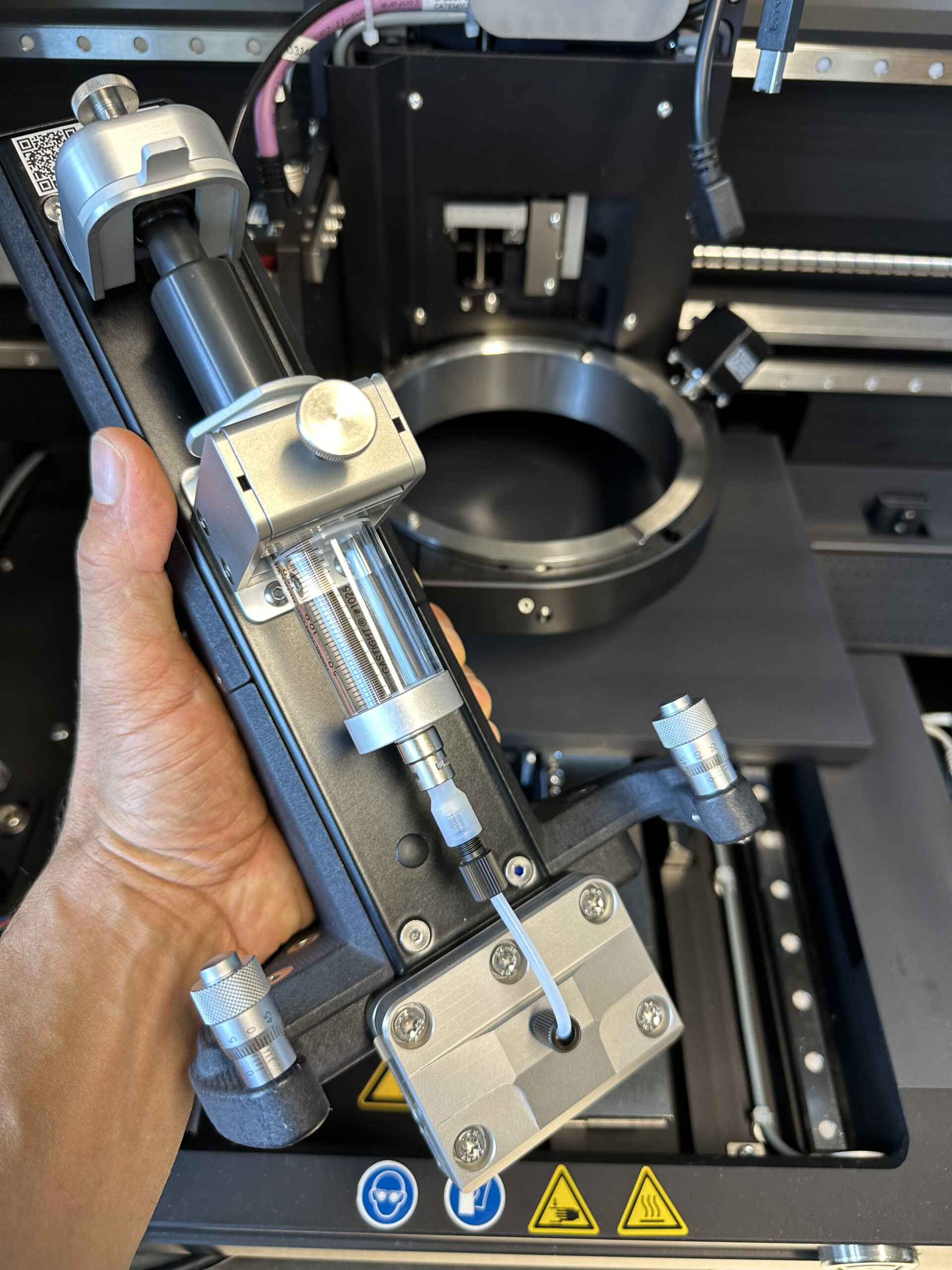

To prevent this we have minimized total dead volume of the entire system by placing the syringe pump very close to the slot die coating head. This unique design allows to minimize tubing and results in a very compact module that can be operated even with the LP50 working in a glovebox. With this you can do both inkjet and slot-die coating with the very same machine.

To achieve a suitable coating result the system allows to adjust all relevant parameters:

- Pump flow rate and off/on trigger via the LP50 in sync with positioning and movement of the slot-die head

- To adjust the coating gap and the parallelity of slot-die head relative to the printing table or the substrate we use the extremely precise camera system of the LP50.

- Coating positions and speed can be programmed in the LP50 so that even multiple coatings next to each other are possible e.g. for parameter studies.

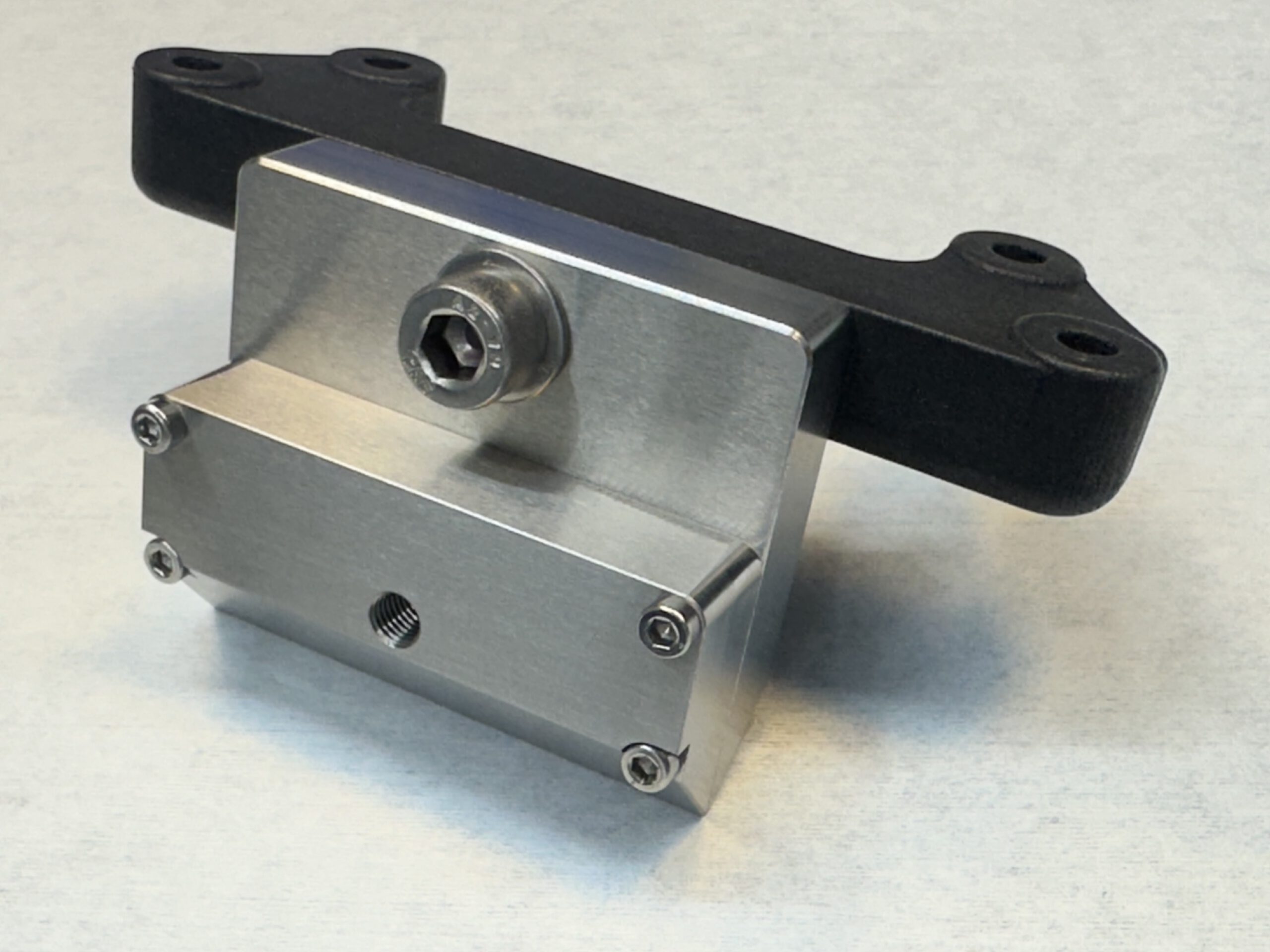

- A unique system of slot-dies and shims provides the flexibility that is needed to work with a large variety of materials

The compact design is also very suitable when it comes to filling the system with your materials and of course when cleaning it after usage. As the complete module can be detached from the printer both processes can be carried out remote from the substrate or the printer minimizing risk of contamination or damage. It can easily be transferred in/out of a glove box as it fits the regular air-lock chambers.

The entire system is designed in a way that it can be fitted with different syringes for small or larger volumes and with different slot-die coating heads (also third party slot-dies can be attached), which can be equipped with different shims for various coating widths and fluid viscosities.