Plasma-Kit for the SUSS LP50

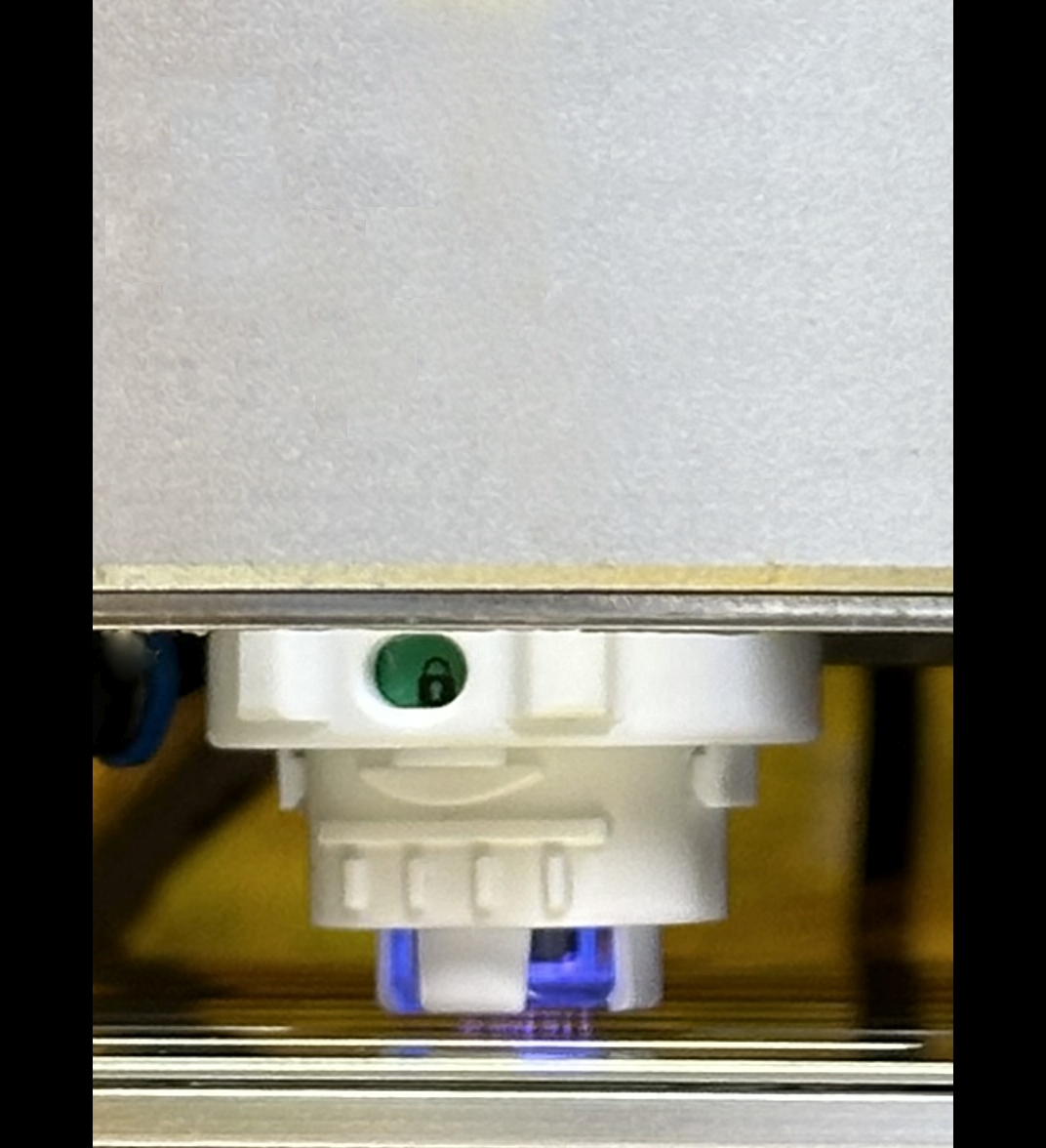

Turn your LP50 in a surface modification powerhouse with the JB Instruments Plasma-Kit. This integration module allows surface activation and functionalization directly before printing, improving adhesion and coating quality without additional process steps. The compact design of this plasma processing tool minimizes footprint and investment, while the precise control system ensures highly repeatable plasma treatments tailored to specific application needs.

While the LP50 is primarily designed for inkjet printing, surface modifications are often necessary to achieve optimal printing results. Adjusting the contact angles is key to a successful print. With our versatile LP50 Plasma Kit, you can treat your samples using a wide range of plasma processes and intensities. Treatment can be applied locally or across the entire surface. In addition to contact angle adjustment, plasma processes can enable many other useful modifications to the samples, providing a range of new possibilities with our plasma tool.

Turn your LP50 in a surface modification powerhouse with the JB Instruments cold Plasma-Kit:

- Surface treatments for electrically conducting and non-conducting materials to tailored surface properties

- Endless applications for improved printability, surface cleaning, or surface activation

- Low impact on the sample by T<50°C

- Low gas flow needed to treat sample (<20l /min)

- Localized or full face treatment of the sample with various process parameters is possible

- Integrated in the LP50 software environment

In many cases, the desired modification of the sample is intended to be limited to its surface. The low plasma temperatures, kept below 50°C, make this possible for a wide range of sample materials. Thanks to the unique design of the plasma source, only minimal gas consumption is required—an advantage not usually associated with cold plasma processes

In research and development and later in production, a variety of material surfaces often need treatment, whether electrically conductive or non-conductive. The plasma source we’ve selected is suitable for both types, ensuring versatility. Its low power and gas consumption enables seamless integration into an easily mountable processing kit for the LP50. Installation takes only a few minutes, and the plasma source is immediately ready to process your sample. Additionally, various interchangeable plasma modules can be effortlessly swapped, offering a wide array of plasma processing options.

Scaling up your research is feasible with this type of plasma source as it is readily available also for large scale production.