Inkjet printing with the Dimatix® Samba® Cartridge on the SUSS LP50

About the Samba® Cartridge

The Samba Cartridge is a small piezo-driven inkjet printhead based on the same advanced jet design as the industrial-scale SAMBA G3L printhead. Unlike the G3L (which has 2048 nozzles and a native resolution of 1200 dpi), the Samba Cartridge is equipped with 12 nozzles (at 75 dpi). Both printheads operate in the viscosity range of around 4-8 cps, and have a drop volume of 2.4pl. Both can be heated to 60°C and can be used with water-based or organic solvent inks. The Samba Cartridge has a 1.5ml fluid module, which allows the cartridge to be used with very small amounts of ink, but still enough to perform decent printing experiments. The Samba Cartridge can be used with the LP50 via the JB Instruments GmbH integration module This makes the Samba Cartridge the ideal platform for inkjet process and materials research and development on the SUSS LP50 inkjet printer with PiXDRO technology, as it allows to work very efficiently and by design ensures that the findings can later be transferred to the scalable G3L printhead for industrial use.

Working with the Samba Cartridge

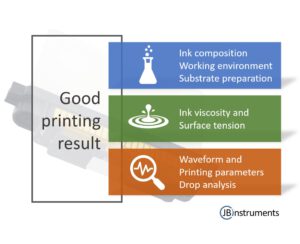

When using the Samba cartridge, be aware that the small nozzles can be easily blocked by dust or other particles. Make sure that your ink and your working environment are clean and run your ink through a 0.2 µm or 0.45 µm filter before loading it into the fluid module. Make sure yor use sub-micron particles in your ink to avoid clogging.

Adjusting the viscosity to the desired range (4-8 cps) is very important as only with a suitable viscosity you will get the print result you want. Firstly, you can influence the viscosity by adjusting the solid content and the liquid components/solvents of your ink. Secondly, for most inks increasing the temperature will reduce the viscosity. As the printhead is able to heat the ink in the nozzle-plate up to 60° C it might be worth a try. The surface tension of your fluid is also important. The Samba Cartridge datasheet suggests a range of 28-32 dynes/cm.

You may also want to experiment with the waveform, the shape of the voltage pulse that causes the nozzle to eject the droplets. The voltage on the Samba Cartridge can be increased up to 40 V, but rembember that too high a voltage cause satellites (unwanted extra droplets ejected from the nozzle). Before turning the voltage knob to the maximum you may want to vary the pulse width. It has a strong effect on the velocity of the droplets, so finding the right pulse width can be a big help your way to the best set of parameters.

Reducing the jetting frequency and overall printing speed may also help to improve results. Use the Dropview station of the LP50 to analyse the effects of your actions on the droplets produced.

Inks to start with

Here are some inks to get you started with setting up an inkjet process with your SAMBA® printhead on the LP50.

- PriElex® SU-8 1.0 Inkjettable dielectric (KAYAKU ADVANCED MATERIALS®)

- XPORGACON® SI-J20x Nanosilver Inkjet Printing Ink (AGFA)

- JS-A191 Silver Nanoparticle Ink (for SAMBA printhead) (Novacentrix®)

Learn more about our samba cartridge integration module for the LP50: